Blog Archives

CX-15 Platform Installed at Corvina Field Offshore Peru

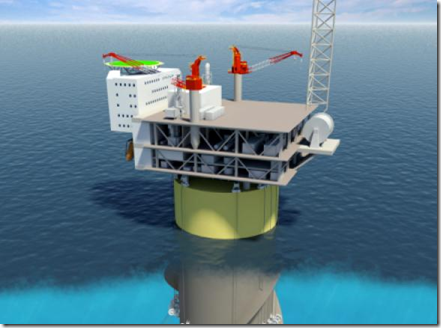

BPZ Energy,an independent oil and gas exploration and production company, announced that the hull tower for the CX-15 platform was successfully floated off the transport vessel, uprighted and ballasted. Subsequently, the topside facility was also successfully mated to the hull tower.

The CX-15 platform is now anchored at the West Corvina field location, one mile south of the existing CX-11 platform.

Welding and other miscellaneous activities are underway and will take approximately two weeks. The Petrex-28 drilling rig, which has been inspected and accepted for work, will then be mobilized to the CX-15 platform. It is expected that the necessary environmental permit required to conduct drilling operations from the CX-15 platform will be received from the Peruvian authorities before the drilling rig is mobilized. The Company expects to spud the first well of the CX-15 drilling campaign in late October.

The CX-15 platform was safely completed and successfully delivered to BPZ Energy at Wison Offshore & Marine’s Nantong, China, fabrication facility in a record 11 months from contract signature and without a single lost time incident. Wison’s scope included the engineering, procurement and construction of the facility’s 2,500 ton Buoyant Tower hull and 1,500 ton topsides facility. This project represents not only the first use of the design, but also the first implementation of Wison’s integrated international delivery model including members from the company’s three operation centers Inc. located in Shanghai and Nantong, China, and Houston, Texas, USA.

The Buoyant Tower hull for the facility was designed and engineered through a joint venture between Wison affiliate, Horton Wison Deepwater, and GMC Limited and consists of four, ring-stiffened connected cylindrical tubes or “cells” with one central suction pile. Each cell measures 8.4 meters in diameter and 60.1 meters long, with a total hull length, including suction pile, of 69.9 meters. This design, which is similar to proven cell spar technology, was a key enabler for the project due to the fact that it will not require a derrick barge for installation as it is located in a region with minimal resident offshore construction vessels.

CX-15 Platform Installed at Corvina Field Offshore Peru| Offshore Energy Today.

USA: Gulf Island Fabrication to Build 335 Class Offshore Liftboat for Montco Offshore

Gulf Island Fabrication, Inc. announced on September 18th 2012, that its subsidiary, Gulf Island Marine Fabricators, L.L.C., signed a contract for the fabrication of a 335 Class, 185 feet long by 135 feet wide by 15 feet deep, offshore liftboat for Montco Offshore, Inc., a marine operator based in Galliano, LA.

When completed, this will be the second 335 Class liftboat the Company has built for Montco Offshore, Inc. Revenue and man-hour backlog related to this project will be included in the Company’s consolidated backlog when the Company announces its earnings results for the quarter ended September 30, 2012.

Gulf Island Fabrication, Inc., based in Houma, Louisiana, is a leading fabricator of offshore drilling and production platforms, hull and/or deck sections of floating production platforms and other specialized structures used in the development and production of offshore oil and gas reserves. These structures include jackets and deck sections of fixed production platforms; hull and/or deck sections of floating production platforms (such as tension leg platforms (“TLPs”), “SPARs,” “FPSOs” and “MinDOCs”), piles, wellhead protectors, subsea templates and various production, compressor and utility modules, offshore living quarters, towboats, liftboats, tanks and barges. The Company also provides offshore interconnect pipe hook-up, inshore marine construction, manufacture and repair of pressure vessels, heavy lifts such as ship integration and TLP module integration, loading and offloading of jack-up drilling rigs, semi-submersible drilling rigs, TLPs, SPARs, or other similar cargo, onshore and offshore scaffolding, piping insulation services, and steel warehousing and sales.

- Gulf Island Fabrication (GIFI) to Build 185ft Long Liftboat (streetinsider.com)

- Superior Energy Reports Solid Operating Results (USA) (mb50.wordpress.com)

BSEE: Production in US GoM Returns to Normal

Offshore oil and gas operators in the Gulf of Mexico continue to restore production following Tropical Storm Isaac. The Bureau of Safety and Environmental Enforcement (BSEE) Hurricane Response Team will continue to work with offshore operators and other state and federal agencies until operations return to normal.

Personnel remain evacuated on a total of 10 production platforms, equivalent to 1.68 percent of the 596 manned platforms in the Gulf of Mexico. Production platforms are the structures located offshore from which oil and natural gas are produced.

Personnel remain evacuated from one rig, equivalent to 1.32 percent of the 76 rigs currently operating in the Gulf. Rigs can include several types of self-contained offshore drilling facilities including jackup rigs, submersibles and semisubmersibles.

BSEE: Production in US GoM Returns to Normal| Offshore Energy Today.

- Gulf of Mexico production ramps up after Isaac (fuelfix.com)

- Gulf Oil Production About 80% Shut-In Due to TS/Hurricane Isaac (247wallst.com)

- Hurricane Isaac’s Impact On Oil Prices Would Likely be Short-term (valuewalk.com)

Noble Energy Linking Noa and Pinnacles to Mari B Platform

Noble Energy and Delek Group have started linking Noa and Pinnacles offshore natural gas fields to the Mari B production platform, according to the Israel’s financial newspaper Globes.

Helix ESG’s reeled pipelay vessel, Express, which in April arrived at the port city of Haifa, Israel has started SURF (Subsea Umbilicals, Risers and Flowlines) work.

According to the data on Noble Energy’s website, Noa will, once developed, provide 100 million cubic feet per day (MMcf/d) of production by September 2012.

Development of the Noa field is geared to allow for additional supplies of natural gas to the Israeli market, until the start of natural gas supplies from the Tamar project.

Related articles

- Oil drilling near Haifa halted (jta.org)

- Noble Energy Provides Update On Leviathan Deep (prnewswire.com)

UK: Flare at Elgin Platform Could Ignite Gas Cloud, Experts Say

The gas leak that occurred at the wellhead platform on the Total-operated Elgin field in the UK North Sea, remains ongoing, the operator reports.

The gas has been flowing since Sunday, March 25th, when Total evacuated all the personnel from the Elgin platform. The precise cause of the gas leak, that has been flowing approximately 240 km east of Aberdeen, is yet to be identified.

According to The Telegraph, experts have warned that the gas cloud which can be seen is very flammable and they described the situation as a disaster waiting to happen because the flare on the Elgin platform is still ongoing.

Total explains that the flare is an integral part of the platform’s safety system, and it is used to safely evacuate all the remaining gas from the platform. The company says that the flare does not pose a threat, because the winds are taking the gas cloud away from the open flame.

“The wind is forecast to remain in its current direction for the coming days. You can be assured that this is being reviewed on a constant basis and should this change any impact is being assessed. In parallel we are investigating solutions to extinguish the flare if it does not burn out by itself.”

Elgin and Franklin are two high pressure/high temperature gas and condensate fields in the Central Graben Area of North Sea. Total E&P UK Limited owns 46.17% and is operator of both fields through its wholly-owned subsidiary EFOG and its average share of production was around 60,000 barrels of oil equivalent per day in 2011.

Elgin/Franklin facilities comprise two wellhead platforms, one on Elgin and one on Franklin and a Production/Utilities/Quarters (PUQ) platform. The PUQ is on the Elgin field and is linked to the Elgin wellhead platform by a 90-metre bridge.

Related articles

- Fitch: Total Gas Leak ‘Not Another Deepwater Horizon’ (mb50.wordpress.com)

- Gas Leak at North Sea Elgin Platform (theoildrum.com)

- ‘One spark and another Piper Alpha on our hands’: Fears grow as explosive gas leak from ‘well from hell’ threatens repeat of Britain’s deadliest rig disaster (dailymail.co.uk)

- Total says finds source of North Sea gas leak (reuters.com)

USA: Hercules Offshore Secures Contract for Newly Bought Rig

Hercules Offshore, Inc. announced yesterday the execution of a definitive agreement to acquire the offshore drilling rig Ocean Columbia from Diamond Offshore Drilling, Inc.

The purchase price is $40 million in cash. Ocean Columbia is a LeTourneau Class 82 SD-C jack-up drilling rig registered and flagged in the Marshall Islands. Subject to customary closing conditions, the Company expects the acquisition to close in May 2012.

“Hercules approached us with an offer to acquire the Ocean Columbia, and we found the terms to be compelling,” said Larry Dickerson, President and Chief Executive Officer of Diamond Offshore. “We are principally a floater company, and this transaction will further augment our funds for potential investments in deepwater and ultra-deepwater assets.”

Saudi Aramco contract

Hercules Offshore also announced that it has entered into a three-year drilling contract with Saudi Aramco for the use of the Ocean Columbia. Over this three-year period, the Company expects to generate total revenues of $160.0 million, including a lump-sum mobilization fee, assuming a utilization rate of 98% for the rig. Under the drilling contract, Saudi Aramco has the option to extend the term for an additional one-year period. Prior to commencing work under the contract, the Company expects to spend approximately $45.0 million for repairs, upgrades and other contract specific refurbishments to the rig and to mobilize the rig from the Gulf of Mexico to the Middle East. The Company expects the rig to commence work under the contract in November 2012.

Related articles

- Hercules sees more rigs in GOM (mb50.wordpress.com)

- Fairstar FJELL to Carry Hercules 185 Jack-up Back to West Africa (mb50.wordpress.com)

- How Will Hercules Offshore Do in 2012? (dailyfinance.com)

- The Best Offshore Drilling Stock (dailyfinance.com)

Aker Solutions to Design World’s Largest Spar Platform for Statoil

Aker Solutions has been awarded a FEED (front-end engineering and design) contract from Statoil to design the world’s largest Spar platform for the Aasta Hansteen field development in the Norwegian Sea.

With a total hull length of 193 meters and a draught of 170 meters, the Aasta Hansteen (formerly named Luva) Spar platform will be the largest of its kind. A Spar platform is a cylinder shaped floating offshore installation. Aasta Hansteen will be the first Spar platform on the Norwegian continental shelf (NCS), and also the world’s first Spar platform with condensate storage capacity – a so called Belly-Spar.

The Belly-Spar concept is an exclusive Aker Solutions design. The ‘belly’ refers to the increased diameter on part of the circular shaped hull, where the condensate storage tanks are located. This gives the Aker Solutions’ Belly-Spar its characteristic shape.

Henning Østvig, head of Front-End & Technology in Aker Solutions says: “The Aasta Hansteen Spar will be the first production platform on the NCS with steel catenary risers. With a water depth of 1300 meters, this is probably the only riser technology that can meet the challenges on the Aasta Hansteen field”.

The steel catenary risers are made of self-supporting steel pipes in a bow shape between the platform and the seabed. The shape helps the risers compensate for the motions on the floating facility.

Innovation

“The Belly-Spar concept is a result of the innovative spirit and culture among our engineers, who have come up with the right solutions for the challenging conditions on the Aasta Hansteen field,” says Valborg Lundegaard, head of Engineering business area in Aker Solutions.

The mooring system for Aasta Hansteen Spar platform consists of a set of polyester lines. “There are currently no installations on the NCS with polyester mooring. Aasta Hansteen may be the first, and it will definitely be operating in the deepest water,” says Henning Østvig.

The FEED study will be completed in the third quarter of 2012. The contract value is undisclosed.

Aasta Hansteen

The field was discovered in 1997 and lies 300km offshore in the Vøring area. The licence partners are Statoil (75 per cent), ExxonMobil (15 per cent) and ConocoPhillips (10 per cent).

Aker Solutions’ contract party is Aker Engineering & Technology AS.

Related articles

- USA: Aker Solutions to Provide Umbilicals for Anadarko’s Lucius Development (mb50.wordpress.com)

- Aker Solutions wins NOK 1 Billion Contract to Upgrade Snorre A Drilling Facilities (gcaptain.com)

- USA: Aker Solutions to Open Hi-Tech Drilling Equipment Simulator in – Houston (mb50.wordpress.com)

- Norway: Aker Solutions Delivers Subsea Templates for Skuld Fast-Track Development (mb50.wordpress.com)

- Aker Solutions to Deliver 6 More Trees to Statoil’s Giant Troll (gcaptain.com)

- Ghana: Aker Solutions Signs Well Service Contract with Tullow (mb50.wordpress.com)

- Norway: EMAS AMC Wins Fram SURF Deal from Statoil (mb50.wordpress.com)

Continents of the World

Continents of the World