Blog Archives

Forum Acquires Dynacon (USA)

Forum Energy Technologies, Inc. announced yesterday, December 3, that it has acquired Dynacon, Inc. (“Dynacon”). Details of the transaction were not disclosed.

Dynacon is the leading provider of launch and recovery systems (“LARS”) used for deployment of remotely operated vehicles (“ROVs”) and also manufactures high quality, specialized cable and umbilical handling equipment for all segments of the marine industry. Dynacon’s Bryan, TX location employs over 100 people and consists of 82,000 square feet of manufacturing and office space and 40,000 square feet of specialized test area located on sixteen acres.

Cris Gaut, Forum’s Chairman and Chief Executive Officer, commented, “Dynacon expands our Subsea Technologies capability and integrates an important part of the ROV supply chain. We plan to continue Dynacon’s long legacy of providing top quality systems to its customers, while investing in the company’s facility in Bryan to expand capacity. We welcome all of the employees of Dynacon to Forum.”

James Stasny, Dynacon’s President and Co-founder, commented, “We are pleased for Dynacon to become a part of Forum. Dynacon’s success has resulted from our employees’ hard work and their commitment to serving the needs of our customers with quality equipment. Forum recognizes the value of Dynacon’s operations and our management team, which will remain in place.”

Forum Acquires Dynacon (USA)| Offshore Energy Today.

- Forum Energy Technologies, Inc. Acquires Dynacon, Inc. (virtual-strategy.com)

Canyon Offshore’s Olympic Triton Returns to the Gulf of Mexico

Add your thoughts here… (optional)

Canyon Offshore is pleased to announce the return of its M/V Olympic Triton to the Gulf of Mexico. She is scheduled to arrive December 2012 and will be available to assist offshore energy producers with ROV vessel needs ranging from high end construction missions to planned or call out ROV inspections.

View original post 101 more words

ExxonMobil Seeks ROV for Operations in Black Sea (Romania)

ExxonMobil Exploration and Production Romania Limited Nassau (Bahamas) is seeking for diving services using a remotely operated vehicle for a drilling programme in the Black Sea.

The objective of the framework agreement is for ExxonMobil to be able to access the resources identified as necessary for the provision of services under the contract.

Minimum and maximum operating 380 – 1,309 days of operation with mobilisation and demobilisation days are included in the tender.

The project has a value between USD8 million and USD30 million with duration of 48 months.

ExxonMobil is expecting the tenders to be submitted until November 06, 2012.

Subsea World News – ExxonMobil Seeks ROV for Operations in Black Sea (Romania).

- Rosneft, ExxonMobil to launch test drilling in Kara, Black seas (english.ruvr.ru)

Oceaneering Charters Subsea Support Vessel from Otto Candies (USA)

Oceaneering International, Inc. announced today that it has entered into a five-year charter for use of the Cade Candies, a multi-service subsea support vessel owned by Otto Candies LLC. The charter is expected to commence during the second quarter of 2013.

This state-of-the-art, U.S. flagged vessel was built in 2010. It has an overall length of approximately 309 feet (94 meters), a Class 2 dynamic positioning system, accommodations for 69 personnel, a helideck, a 150-ton active heave compensated crane, and a working moonpool.

Oceaneering’s current rolling, short-term charter contract on the Cade Candies, in place since November 2011, will continue through early 2013. At that time, the vessel will enter a shipyard to undergo modifications to enhance its project capabilities. While in the shipyard, Oceaneering’s two, high-specification, work class ROVs onboard the vessel will be repositioned and fully integrated into the vessel for more effective operations. The vessel will also be equipped with a satellite communications system capable of transmitting streaming video for real-time work observation by shore personnel.

To be renamed the Ocean Alliance, the vessel will be used to augment Oceaneering’s ability to provide subsea intervention services in the ultra-deep waters of the Gulf of Mexico (GOM). These services are required to perform inspection, maintenance, and repair (IMR) projects and hardware installations. IMR projects are expected to include chemical well stimulation and hydrate remediation. Hardware installations are expected to include umbilicals, subsea trees, flowline jumpers, flying leads, and manifolds.

M. Kevin McEvoy, President and Chief Executive Officer, stated, “We are very pleased to have added, on a long-term basis, this modern, high-end, Jones Act-compliant vessel to our suite of assets to enhance our capabilities to serve our customers in the deepwater GOM. This charter demonstrates our belief the GOM deepwater subsea intervention market has a promising and sustainable future.”

Oceaneering Charters Subsea Support Vessel from Otto Candies (USA)| Offshore Energy Today.

- USA: Oceaneering Charters IMR ‘Cade Candies’ Vessel (worldmaritimenews.com)

- Oceaneering International Secures Cade Candies in Five Year Deal (gcaptain.com)

Helix ROV Support Vessel Ready for North Sea

Helix Energy Solutions Group’s newbuild charter ROV support vessel, Grand Canyon, recently completed sea trials and is ready to begin operations in the North Sea. During the sea trials the vessel’s propulsion system, dynamic positioning system and all her cranes were tested.

The vessel recently completed its outfitting in Norway after the initial hull construction was completed in Turkey. Grand Canyon is capable of launching five ROVs at once and will be operated by Helix ESG’s robotics subsidiary, Canyon Offshore.

The vessel will be the new home for another recently completed asset, the T1200 trenching unit. Used primarily to bury large diameter power cables leading from offshore windfarms, the T1200 is also capable of working on oil and gas projects to bury production pipelines.

The Grand Canyon was designed to provide a high capacity, stable working platform for lay, burial and general offshore construction work while still retaining a shallow draft, which is crucial when operating close to the coastline, and common in the renewable energy sector.Grand Canyon’s DP3 capability allows her to operate in any sector, providing offshore support in a wide variety of roles.

The vessel’s deck structure is specifically designed to accept trenching and flexible pipe or cable lay systems for safe and efficient mobilizations. A key focus throughout the design and build of Grand Canyon was to optimize the vessel and equipment design to facilitate efficient mobilizations.

Helix ROV Support Vessel Ready for North Sea | Offshore Energy Today.

- ROV Support Vessel Grand Canyon Completes Sea Trials (Norway) (worldmaritimenews.com)

- North Sea Rig Rates May Push Higher as Midwater Market Heats Up (gcaptain.com)

- UK: Helix Well Ops Charters Skandi Constructor from DOF Subsea (mb50.wordpress.com)

USA: Sub Sea Research Locates Port Nicholson Shipwreck

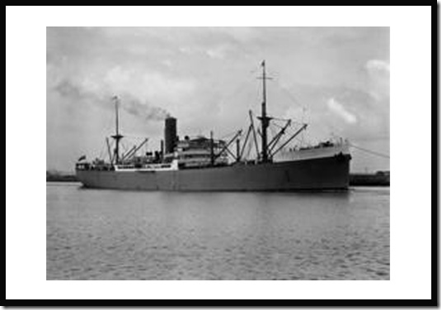

Sub Sea Research LLC, a Portland Maine based company located the worlds richest shipwreck, a WWII British Freighter carrying a secret cargo of 71 tons of Platinum sunk by a German U-Boat off the coast of Cape Cod.

Sub Sea Research (SSR) spent months searching for the elusive ship, the Port Nicholson, torpedoed by German U-boat U87, June 1942. It took two torpedoes and about 7 hours to sink her. U-87 also fired at the troop ship the “Cherokee,” quickly sinking her with a heavy loss of lives.

The Port Nicholson is a steel-hulled, 481 ft. merchant ship, coal fired freighter built in 1918 at the Tynes & Wear shipyard. She was carrying two special envoy USSR agents overseeing the delivery of a very important Lend-Lease payment from the USSR to USA. She along with 4 other commercial vessels were being escorted by an unusually high number of military ships. The normal ratio at the time was near 1:10 or less but this convoy ratio was 6:5. Maybe it was the fact they were delivering 1,707,000 oz. troy, in 400 oz. bars of platinum. Strangely the two USSR special envoy individuals quickly disappeared after being rescued and brought to American shores. They were not de-briefed like all the other survivors were.

SSR first discovered the Port Nicholson in 600-800 feet of water off Cape Cod in 2008. In 2009 SSR obtained legal recognition from the US Courts as the legal owner and salvager of the ship.

SSR researchers corresponded with individuals manning the ships and even spoke with another U-boat captain who was in the same area. They have talked with survivors and relatives of the men of the Port Nicholson and the Cherokee. One Yarmouth, MA author has written a book and is waiting for “the last chapter” of raising the valuable cargo of the Port Nicholson. These researchers also found declassified documents verifying the cargo as well as the debriefing of the sinking.

According to SSR research, the Port Nicholson and four other ships were being escorted by six military ships in a convoy from Halifax to New York. The Port Nicholson is documented to be carrying ~1,707,000 troy ounces of platinum. It may also contain $165M of copper, zinc and war stores. Greg Brooks, one of two SSR founders, said his team has already recovered several identifying and critical artifacts. He has verified that “it is without a doubt the Port Nicholson”.

Late in the summer of 2011, after 100’s of hours of ROV video, they have seen what appear to be bullion boxes containing 4 bars, each being 400 troy ounces of precious metal. “We have seen boxes indicative of those used to store and ship this type of bullion in 1942. Our video clearly shows the box and our inspection class remotely operated vehicles (ROV) could not lift it due to its weight of about 130 lbs.”

A similar discovery occurred in 1981 when the HMS Edinburgh was discovered in the Barents Sea. It too carried a USSR Lend-lease payment. This wreck, in 800 feet of water, took almost three years to salvage in 1981 (Salvage of the Century) and contained $100M of gold (1981 prices). Richard Wharton, one of the original salvagers, provided SSR with photos and dimensions of the wooden boxes from the HMS Edinburg containing the gold bullion bars. These wooden bullion boxes were the same type shipped within six weeks of the Port Nicholson. According to Brooks, “We used our manipulator arm to scale our box dimensions. They appear close and almost exactly match the boxes salvaged in 1981. Mr. Wharton’s photos are almost identical to the boxes we have seen on our wreck. We nudged and pushed the boxes with maximum thrust from our ROV. We have verified these boxes have unusually high mass as one would expect for bullion. What is different from the Edinburgh boxes and unique to ours is that ours are very well preserved and do not easily come apart. Things are very well preserved. We even flipped the pages in a book and the pages remained intact. That was amazing to see.”

“We have been working and planning the site since 2009. Our current equipment is just not enough to handle the 2-5 knot currents, mostly zero visibility and the excessive ocean conditions at the site. It takes us 10 hours from Boston Harbor to get to the site. And, conditions such as these leave few and very small windows of onsite time each year in which we can safely work on the site. We certainly underestimated the conditions and maybe over estimated our capacity even with the 214 ft. M/S Sea Hunter and a 95 ft. ship M/S Son Worshipper fully equipped with a sub, ROVs, 125 ton crane, claw and sonar gear.

Photos taken from the HMCS Nanaimo at the time of the sinking show the Port Nicholson bow straight up in the air. She went down straight and slammed to the bottom vertically, stern first at about 30 mph and is now lying on her starboard side. This position, along with the numerous metal, wires, pipes, booms, debris as well as 70 years accumulation of fishing net snags makes access extremely difficult from the deck side. “The holds are not upright and we certainly are not simply going down into the holds with a lift and pulling up the cargo. We may have to cut into the hull to gain access and that is complicated and requires a different tool set. The ship carried war stores thus requiring even greater caution and safety procedures.”

“There is nothing more frustrating for each of our crew, as well as our financial supporters, to see, touch and feel the bullion box and not be able to quickly and simply retrieve it. There is nobody on this earth who wants to bring up that box more than me. We’ve been at it a while now.”

While the ship, M/S Sea Hunter is capable of remaining on-site in almost any weather, SSR has exhausted the capability of the ROV and support equipment. SSR is now entertaining private support from special technical and financial organizations. The operation needs to re-capitalize so that SSR can order or retain a heavy duty state of the art work class ROV, fully outfitted with the tool set to complete the salvage and bring a bar on deck. This specialized equipment costs about $2.5M, requires well trained support crews and is capable of lifting heavy loads and has a long build/lease lead time of up to 20 weeks.

“Many marine technology firms are very interested in helping and being part of such an exciting treasure salvage project right in Boston’s back yard. They want to share in this once in life time adventure. And, it has a rich local and national history with a high degree of intrigue.”

“We have spoken with some interesting individuals and some family investment groups who are bored with traditional opportunities. They are certainly tired of the significant swings and losses occurring in the market today. They are most intrigued with the unique sense of history and adventure the Port Nicholson treasure simply from the excitement factor.

“Who wouldn’t want to be a treasure hunter, have a real piece of history (1942 platinum) and be able to say ‘I am a real treasure hunter’. It is every kid’s dream to be a treasure hunter and some adults dream of it too!”

“All we have left to do is get the right equipment to bring up the bars we have seen. 2012 is our year to make this all come to fruition!”

Sub Sea Research LLC (SSR), a Maine company founded in 1994, maintains a fleet of ships and scientific exploration equipment to engage in research, conservation, development and exploration activities around the world aimed at finding, recovering or preserving underwater shipwrecks of special historical and cultural significance.

Related articles

- Ireland: Odyssey Conducts Search Operations for SS Gairsoppa Using Research Vessel Yuzhmorgeologiya

- Odyssey Confirms Identity and Location of SS Gairsoppa Shipwreck (Ireland)

- Astrakhan Shipyard Builds Project 22870 Salvage Ship for Russian Navy

- SCTA Starts Salvage Wreckage Works at Qunfudah Port (Saudi Arabia)

- Odyssey Discovers Second Silver Cargo Shipwreck Offshore Ireland

Related articles

- The Largest Treasure Find Ever – How Nazi’s Found and Sunk The British Treasury Ship Gairsoppa (gcaptain.com)

- Shipwreck Hunters Find Millenium Falcon Shaped Object On Sea Floor [Video] (inquisitr.com)

- Treasure hunters say Irish waters have valuable wrecks – Irish Times (news.google.com)

- Silver worth $18 million found on bottom of North Atlantic; ship carrying treasure sunk by torpedo in 1917 – @nytimes (nytimes.com)

USA: FMC Technologies Buys Remaining Schilling Shares

FMC Technologies, Inc. has exercised its purchase option for the remaining 55% of outstanding shares of Schilling Robotics LLC (“Schilling”).

FMC purchased its existing 45% interest in Schilling and obtained the purchase option in 2008.

Schilling is a leading producer of remotely operated vehicles (“ROVs”), ROV manipulator systems, control systems and other high-technology equipment and services for oil and gas subsea exploration and production. FMC and Schilling have collaborated on a variety of projects and technology advances over the past three years, including an innovative control system for Petrobras’ Congro/Corvina project that will use subsea robotics technology to operate the manifold and separation station valves.

“We are pleased that Schilling will become part of FMC,” said John Gremp, Chairman, President and CEO of FMC Technologies. “Their technologies will help us develop additional solutions to further strengthen our subsea leadership position.”

Tyler Schilling, Chairman and President of Schilling, added, “Since partnering with FMC in 2008, we have expanded our global presence and participated in some of the industry’s most innovative projects. Our employees are excited about joining FMC and the future opportunities that exist to develop subsea technologies for our customers.”

Articles

- UK: Subsea 7 Selects Schilling Robotics’ ROVs to Support its Offshore Operations

- USA: Global Industries Orders New Schilling UHD ROV

- Norway: DOF Subsea Expands its Fleet with Two Schilling Robotics’ ROVs

- USA: Schilling Robotics’ ROV Earns Prestigious Award

- USA: Schilling Robotics and Gregg Marine Successfully Complete Field Testing on New Seafloor Drill

Related articles

- USA: FMC Technologies Wins Subsea Systems Contract from LLOG – Who Dat project (mb50.wordpress.com)

- USA: FMC Technologies Inks Global Alliance Agreement with Anadarko Petroleum (mb50.wordpress.com)

- Shell Perdido: The first full field subsea separation and pumping system in the Gulf of Mexico. (video) (mb50.wordpress.com)

- Worldwide: Project Field Development News (mb50.wordpress.com)

Continents of the World

Continents of the World