Blog Archives

Telemark

Mirage/Morgus

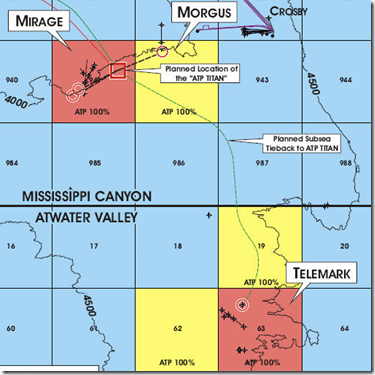

Phase I of the project focuses on the northern part of the greater Telemark area, which includes the Mirage and Morgus fields.

Located on Mississippi Canyon Block 941 in a water depth of 3,800 feet (1,158 meters), the Mirage field was discovered in 1998 when a well encountered roughly 87 feet (27 meters) of hydrocarbons in two sands. The Morgus field is located on Mississippi Canyon Block 942 in 4,304 feet (1,312 meters) of water, and was discovered when drilling encountered approximately 55 feet (17 meters) of net pay.

In an effort to cut costs, ATP decided to jointly develop these fields due to their close proximity. Combined, Mirage and Morgus hold estimated recoverable reserves of 190 Bcf (5 Bcm).

In 2008, the West Sirius semisub drilled three wells on the Mirage and Morgus fields and reached a total depth of 5,900 feet (1,798 meters) in 3,927 feet (1,197 meters) of water.

To develop the Mirage field, Technip received a contract for the flowlines, risers, jumpers and subsea structures. The contract covered engineering for the installation, welding and installation of two steel catenery risers and two oil and gas export flowlines; fabrication and installation of subsea structures and jumpers and pre-commissioning of the project.

Mirage is operated by ATP, which owns a 25% interest; Statoil owns the remaining 75% interest. Morgus is operated by ATP, but Statoil owns 100% of the interest.

Telemark

Phase II of the project focuses on the Telemark field. Telemark is situated in a water depth of 4,300 feet (1,311 meters) on Atwater Valley Block 63. ATP acquired the field in 2006 and owns 97% interest; BHP Billiton holds 1% interest; Chevron holds 1% interest; and Eni holds the remaining 1% interest.

The field was discovered in 2003 in the southern part of the greater Telemark area when exploratory drilling encountered 140 feet (43 meters) of hydrocarbons in the Miocene sands. The Telemark field was deemed commercially viable shortly after, and ATP began field development preparations.

Situated 7 miles south of the Mirage and Morgus fields, Telemark originally was designed to have its own production hub, a MinDOC II, but the company decided to tie-back the field’s subsea well to the ATP Titan, as well. This development will result in an increase in production rates through ATP Titan in 2010 and 2011.

In May 2009, Bluewater Industries received a contract for the field’s development. The contract covers the design and manufacture of one high-pressure flexible riser measuring 2 miles (3 kilometers) long, and engineering for the installation and welding of one oil and gas production flowline approximately 13 miles (21 kilometers) long. The contact also includes installation of a flowline and associated riser with an option to install an umbilical; fabrication and installation of subsea structures and a jumper; and pre-commissioning of the project.

ATP Titan

In 2007, ATP decided to develop the Telemark area with a floating, drilling and production triple-column spar, the ATP Titan, since accessible infrastructure wasn’t nearby. The MinDOC, a deep draft floating platform, is comprised of three columns linked by pontoons, boasting a higher load capacity and enhanced stability than previous designed semisubmersibles or spars.

In 2007, construction of the ATP Titan MinDOC commenced with construction slated to end in the third quarter of 2009. The facility has a design capacity of 25 Mbopd and 60 MMcf/d (2 MMcm/d) and incoporates six dry tree wellheads with three pairs of future subsea flowlines. Mustang Engineering received a contract to provide detailed engineering and procurement support for the topsides production facilities on the ATP Titan.

Towards the end of 2009, ATP Titan was moored at the Mirage and Morgus fields to complete the drilling of three wells to vertical depths of 14,500 to 17,250 feet (4,420 to 5,258 meters). The vessel will serve as the production platform for the life of the fields’ reserves. Then, ATP Titan will move to the Telemark field to recover its remaining reserves once the vessel has finished producing from the Mirage and Morgus fields.

First production from the Telemark Hub commenced on March 28, 2010, and the vessel has an estimated life span of 40 years.

Future Exploration

A fourth field that is 100% owned and operated by APT — Oasis — is located on Mississippi Canyon Block 943, and may be tied-back to the platform, pending exploration results.

Related articles

- Statoil: Riserless light well intervention (mb50.wordpress.com)

- Mexico: Cal Dive to Install Subsea Pipeline in Abkatun Offshore Field (mb50.wordpress.com)

- Gulf of Mexico: Vector Lands Cascade Chinook Field Job (mb50.wordpress.com)

- Shell Perdido: The first full field subsea separation and pumping system in the Gulf of Mexico. (video) (mb50.wordpress.com)

- Perdido Subsea System (video) (mb50.wordpress.com)

Transocean’s Discoverer Americas Gets it Done for Statoil in the Gulf of Mexico

By Rob Almeida On November 4, 2011

It’s about a two and a half hour helicopter flight from Louisiana to get to this lonely patch of ocean far out in the Gulf of Mexico, but the Geoscientists at Statoil said that’s where the oil would be. They called the spot Logan and was located at block 969 in Walker Ridge.

Looking at a chart of the Gulf of Mexico, that’s way the heck out there.

For the past 6 months, the Discoverer Americas, a 6th-generation drillship owned by Transocean, has been sitting out there, precisely on station in around 7800 feet of seawater… slowly turning a drill string dangling far beneath the ship.

This rig is one of the newest in Transocean’s fleet, and her dual activity derrick and highly experienced personnel made her certainly one of the most capable. Built at DSME in Okpo, Korea, her Commissioning Manager, a former US Marine officer and Citadel grad, did an impeccable job in making sure she was ready to go to work as soon as the time came to leave the shipyard back in 2009.

Over the past two years, she covered a lot of ground crossing the Indian Ocean, South Atlantic, and then the Gulf of Mexico before starting on her first well in Mississippi Canyon at a well site called Krakatoa.

It was a heck of a well to start with, and at times her name seemed to be a good fit. After many months on the ocean, while enduring a frigid winter on the Gulf, and countless drilling challenges, the Deepwater Horizon exploded, bringing Gulf of Mexico drilling operations to a screeching halt.

Discoverer Americas off Durban, South Africa, Image (c) Robert Almeida

A few months later, Statoil decided it was time to cram as much gear on board as possible and point the Americas’ bow east, and head back across the Atlantic. Next stop Egypt.

Drilling operations began in a pretty straightforward manner, not many issues. It was deep water, but a relatively shallow well. Or so they thought.

Thousands upon thousands of feet down they drilled, but still nothing. No signs of hydrocarbons, but soon the question of what to do next was once again answered for them.

Egypt erupted in a revolution, ending all possible support from shore. Cairo-based personnel from Statoil and Transocean left town as fast as they could, and soon thereafter, the Discoverer Americas pulled their riser and followed suit, back across the Atlantic Ocean to the Gulf of Mexico.

This was her forth major ocean crossing in 3 years, and she had yet to hit paydirt. Logan had been on the plans ever since she arrived in the Gulf of Mexico a year earlier, and now was the time to earn their paycheck, and hopefully give Statoil the return on investment they were looking for.

This past April, the Logan well was “spud-in” with 36-in casing, officially starting the top section of what would end up being an enormous steel and concrete structure extending miles down below the sea floor of the Gulf of Mexico. Over the next few months as they drilled through dozens of different sediment layers such as shale, sand, and thousands of feet of salt while carefully shoring up the well from the internal pressures of the earth with strings of steel pipe.

The geologists on board carefully analyzed the drill cuttings entrapped in mud that was returning back to the surface. They were looking for the dead remnants of ancient organisms deposited long ago. Finding the right type of organism would be a clue that hydrocarbon-rich sands were close by.

After 6 months of drilling, with their drill string extended nearly 5 miles into the earth, they found what they were looking for. Their polycrystalline, diamond-studded drill bit had finally cut through a formation that was saturated with oil. It was the Americas’ and Statoil’s first find in nearly two years of drilling. Very little public information about how much oil was found and its properties is available however outside of the inner circles at Statoil.

Even Transocean has no idea how much, or exactly what was found, but at the end of the day, none of that matters.

As an offshore drilling contractor, they safely executed an incredibly complex drilling program in waters over a mile and a half deep, allowing their client to gain incredibly detailed and valuable information about the geology present in the Gulf of Mexico.

Next up for the Discoverer Americas is a few month drilling contract for Anadarko at the Heidelberg Prospect in Green Canyon. Sitting below 5,000 feet of seawater, this well will reach over 30,000 feet below the wave tops to an area that has already proven to hold a significant amount of high quality oil-bearing sands.

Congrats to Transocean and the crew of the Discoverer Americas for a job well done.

Related Posts:

- Statoil and Transocean pull out of Egypt

- Transocean to Buy Norwegian Firm Aker Drilling

- Transocean CEO on new contracts, speculative shipbuilding, and the Deepwater Horizon [WEBCAST BREAKDOWN]

Related articles

- Gulf of Mexico: Vector Lands Cascade Chinook Field Job (mb50.wordpress.com)

- Hess to spend $2.3 billion to develop Gulf of Mexico oil field (mb50.wordpress.com)

- USA: Statoil Signs Energy Partneship Agreement with UT (mb50.wordpress.com)

Shell Awards McDermott Contract for Platform Fabrication in U.S. Gulf of Mexico

McDermott International, Inc., announced today that one of its subsidiaries has been awarded a fabrication contract by Shell Offshore Inc., for the West Delta 143 “C” deck, jacket, piles, and bridge located in 370 feet of water in the Gulf of Mexico. The contract will be included in McDermott’s third quarter 2011 bookings.

“We are pleased to be able to offer a competitive solution for the development of the West Delta platform,” said Stephen M. Johnson, McDermott’s Chairman, President and Chief Executive Officer. “Shell’s recognition of McDermott as a “Green Light” contractor for HSES performance, as well as their familiarity with our project management, ability to accelerate schedules and knowledge of our performance quality is where we added value with this contract.”

McDermott’s engineering group based in New Orleans will perform detailed construction engineering and load-out analysis for the 10,120-tons of structures. McDermott’s Morgan City fabrication facility in Louisiana will perform all construction engineering, procurement, fabrication and onshore mechanical completion of the deck. McDermott will also assist in the commissioning of the platform.

First steel cut is scheduled to begin later this year, with expected sail away of the deck in the first quarter of 2013.

The WD 143 “C” fabrication is part of the Mars B Development, which consists of the Olympus Tension Leg Platform, West Boreas and South Deimos subsea development and the West Delta 143 “C” Jacket and Deck. The Olympus host will be located in Mississippi Canyon Block 807 in the Gulf of Mexico approximately 95 miles south of New Orleans, Louisiana, in a water depth of approximately 3,000 feet and its export pipelines will be tied back to the new WD 143 “C” platform.

More about McDermott’s Morgan City Fabrication Facility and Working with Shell

McDermott’s Morgan City fabrication facility covers more than 300 acres and has constructed some of the company’s largest structures. It consistently delivers high-quality projects safely and on schedule, including large integrated platforms and subsea components. Located in Louisiana, the Morgan City yard has fabricated the previous Shell WD 143 “B” platform, as well as several TLP decks including Auger, Mars, Ram-Powell, Ursa, and Brutus.

Continents of the World

Continents of the World